HDPE Pipe Welding Machines

Butt Fusion Welding Machines

We have been supplying HDPE pipe welding machines ranging from 32mm to 1200mm in the Middle East since 10 years. Our welding machines are affordable , reliable and high quality with low maintenance. We also provide HDPE pipe welding machines rental services in UAE.

Manual

Hydraulic butt welding machine Ø 40 – 1200 mm. Selection of components with a long service life ensures a low maintenance, robust and reliable operating mode. For heating element butt welding of PE, PP and PVDF pipes and moulded bodies. For use on the building site, in pipe trenches, on pipe bridges and in workshops. The ROWELD Hydraulic type Professional with infinite pressure adjustment, an easily legible manometer and pressure reservoir for welding according to DVS and other internationally valid guidelines and standardsWith automatic control (CNC) and data recording

Hydraulic butt-welding machine Ø 90- 630 mm. The Premium CNC System enables a nearly fully automated operation. All parameters are documented automatically. The ROWELD® Hydraulic Premium CNC with integrated CNC control and touch screen panel for the quick and reliable saving of the welding parameters in accordance with DVS and other applicable international guidelines and standards. Data transfer via USB interface.Electro Fusion Welding Machines

Two universal electrofusion welding units for PE- and PP-fittings up to 400 and up to 1200 mm diameter.

Universal electro-fusion welding unit for drainage pipe with welding sockets up to Ø 160 mm

KEY FEATURES

- Safety: The Heat-Control (HC) function evaluates based on ambient temperature, device temperature and fitting and checks if the next fitting can be welded completely. This process is fully automated and indicated through a green or a red light shown on the display.

- Performance: Due to the Active-Cooling (AC) function, the unit is ideally fitted for continuous use since the heat removal is maximised by the installed ventilator.

- Complete solution: Ideal for use on a job site. All cables are securely stowed away inside the robust housing. The housing also offers sufficient space for accessories, tools or fittings.

- Read out software for free: all saved welding sequences can be transferred to a computer with a USB drive. From the computer the data can be archived and printed using the read out programme “RODATA 2.0“.

- Barcode Generator: RODATA 2.0 offers also the possibility to encrypt the name of the welder and the name of the construction site as a barcode. This barcode can then be scanned at the job site.

- The status of the welding and the cooling time is displayed by a progress bar.

- Before the welding begins the unit automatically checks for the correct fitting.

ROWELD® ROFUSE Sani 160 Key Features

- Microprocessor-controlled welding unit with automatic temperature compensation of the welding time

- Visual monitoring of the welding process

- Large operating radius

- Robust and impact resistant casing (IP 44)

- Automatic welding parameter settings

KEY FEATURES

- Safety: The Heat-Control (HC) function evaluates based on ambient temperature, device temperature and fitting and checks if the next fitting can be welded completely. This process is fully automated and indicated through a green or a red light shown on the display.

- Performance: Due to the Active-Cooling (AC) function, the unit is ideally fitted for continuous use since the heat removal is maximised by the installed ventilator.

- Complete solution: Ideal for use on a job site. All cables are securely stowed away inside the robust housing. The housing also offers sufficient space for accessories, tools or fittings.

- Read out software for free: all saved welding sequences can be transferred to a computer with a USB drive. From the computer the data can be archived and printed using the read out programme “RODATA 2.0“.

- Barcode Generator: RODATA 2.0 offers also the possibility to encrypt the name of the welder and the name of the construction site as a barcode. This barcode can then be scanned at the job site.

- The status of the welding and the cooling time is displayed by a progress bar.

- Before the welding begins the unit automatically checks for the correct fitting.

ROWELD® ROFUSE Sani 160 Key Features

- Microprocessor-controlled welding unit with automatic temperature compensation of the welding time

- Visual monitoring of the welding process

- Large operating radius

- Robust and impact resistant casing (IP 44)

- Automatic welding parameter settings

Socket Welding

ROWELD® P 63 S - 6 SWORD

Socket welding unit Ø 20 – 63 mm for use with heating spigots and heating sockets.

With three simultaneously usable combinations for welding sockets, pipes and fittings according to DVS guidelines. With a high-quality PTFE anti-stick coating with a long service life.

ROWELD® P 125

Socket welding unit for use with heating spigots and heating sockets for Ø 16 – 125 mm, as well as adaptor plates for butt welding

With three simultaneously usable welding combinations for free-handed working or workbench assembly using table mounting clamp. Heating spigots and heating sockets with a high-quality PTFE anti-stick coating with a long service life

ADVANCE FEATURES

- The LWS PLC does automatically automatically during the welding, the prefix is included in the cooling process for cooling with time and pressure data. Get personal data via USB.

- The LWS heating plate comes with microprocessor based PID digital temperature controller for butt fusion welding of PE, PP, PPH & PVDF pipes & fittings.

ROWELD® P 125

- Socket welding unit for use with heating spigots and heating sockets for Ø 16 – 125 mm, as well as adaptor plates for butt welding

- With three simultaneously usable welding combinations for free-handed working or workbench assembly using table mounting clamp. Heating spigots and heating sockets with a high-quality PTFE anti-stick coating with a long service life

Testing & Leak Detection

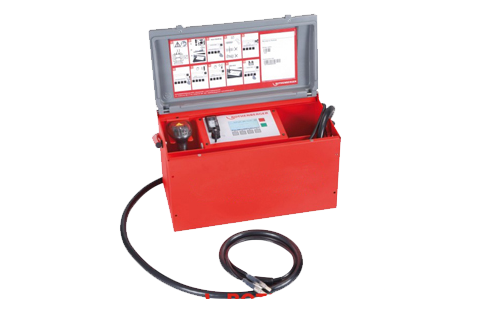

RP Pro III Electric Pressure Testing

Compact and portable unit for rapid and accurate pressure testing

Compact and portable unit for rapid and accurate testing of pipework and systems up to 40 bar (560 psi) in one operation, can be mains water connected or self drawing. Multiple tests can be carried out with optional additional “lock off” testing gauges

HDPE Pump

Extra pressure gauge

Maintenance package for valves TP 25

RP PRO III

Self-priming electric testing pump up to 40 bar

RP 30

Simple and light testing pump for compression testing up to 30 bar

TP 25

Small, robust precision testing pump for pressure testing up to 25 bar

Extra 16 bar pressure gauge with drag indicator R1/4

Extra fine scaling Pressure gauge for the testing of systems up to 16 bar with a 0.1 scaling

RP 50-S / RP 50-S INOX

Robust precision testing pump for the pressure testing of water lines and containers up to 60 bar with very high testing standards